KAOLIN - PROPERTIES, USES IN CERAMIC PRODUCTION

Kaolin is one of the most important clay mineral. It is also sometimes known as China clay and tends to be white in colour, though this can vary. The Kaolin production process consists of several stages. Kaolin preparation processes include wet and dry process.

Kaolin production

Initially, Kaolin was mined at the mine as raw material. The material is then washed with water and filtered to remove impurities and have a large size. Particles that pass through the membrane will flow into a reservoir. At this time, the kaolin water will be passed through a suitable sized filter to get the right size kaolin particles as required. Kaolin water continues to be directed to a storage tank. From this storage tank, aqueous kaolin solutions are pumped into hydraulic presses. By pressing pressure, water will be maximized, wet kaolin is obtained with 30% moisture. After drying, the moisture is about 16%.

Uses of Kaolin in Ceramic production

One of the most prevalent industrial uses of kaolin is in manufacturing ceramics, porcelain ware and floor or wall tiles. Because of its ideal properties for ceramic manufacturing, some people call kaolin clay china clay for its role in producing whiteware. Kaolin clay has a high fusion temperature, and its naturally bright white color makes it useful for manufacturing pure white ceramics, porcelain, china, sanitary ware and kaolin pottery.

Because kaolin contains low concentrations of iron or alkalis, it is ideal for use in various forms of ceramics. When producing ceramics and whiteware, manufacturers usually combine kaolin with additional silica and feldspar, along with a small amount of another type of clay called ball clay, which is a plastic light-burning clay. The combination of kaolin and other ingredients allows ceramic manufacturers to achieve the ideal plasticity, shrinkage, vitrification and other processes to properly shape and heat the ware. Kaolin offers high dry strength, meaning that as an additive, it helps reinforce and strengthen the final product, which is crucial in manufacturing ceramic ware.

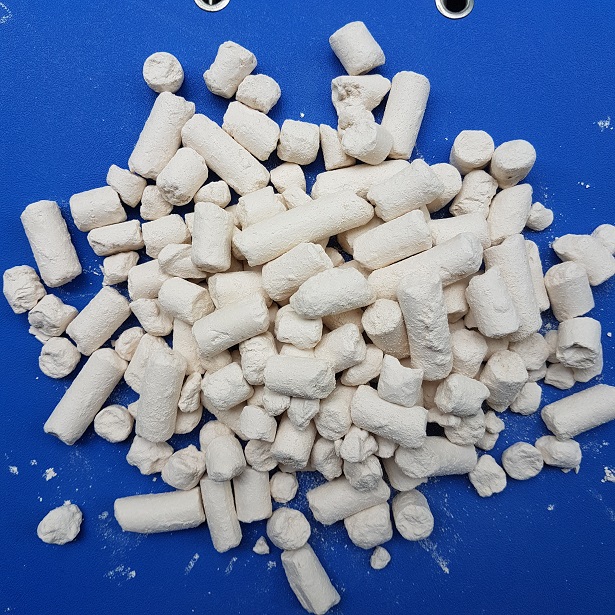

We mainly develop water - washed kaolin for ceramic production in noodle form, cake type, and selected ores in lumps.

Please feel free to contact us for more information and to get the best quotes:

Mr. Steve Dam (International Sales Dept)

Phone/ WhatsApp/ Skype: +84 93 618 1398

Email: export4@shcgroup.vn