The ultimate goal for every human worldwide is to be happy. Certainly, for feed manufacturers, the goal is to be happy in the knowledge that they produce pet food and animal or fish feed with the best possible nutritional and physical quality, in the cheapest possible way. ( Resourse: Dejan Miladinovic - Feed technology)

No doubt that pelleting and extrusion technologies are the most popular thermal processing techniques in the feed industry. These techniques are cost efficient and bring chemical changes that optimise animal digestibility of the feed diets.

It is of paramount importance that by using the scientific methods we identify how combined influencing factors may positively influence an optimal energy consumption during feed manufacturing. Photo: Dreamstime

Influencing nutritional and physical quality of pellets

Process parameters between those techniques contrast each other with physical forces applied during production. Also, their thermal profile together with viscoelastic properties can influence the nutritional and physical quality of the feed pellets.

Many factors can affect physical quality, such as:

- nutritional composition of the feed mash,

- homogeneity of nutrients,

- particle size distribution of the milled ingredients,

- conditioning time and temperature,

- water addition,

- steam quality, etc..

There is a gap in scientific literature that explains how mentioned factors and their combination may influence processability, energy consumption, pallatability and physical properties of the final product.

Not all nutrients are equal

Science knows that all nutrients are not created equal. The nature of proteins or starch defer from one to another raw ingredient. Each ingredient in a feed formulation has a specific function. Therefore, if a certain ingredient is cheaper to use, it does not necessarily follow that that ingredient will be the cheapest option due to the sacrifice of physical feed quality or decreased production outputs.

Influencing physical pellet quality

Feed formulation and viscosity of the feed mash, together with thermal processing, are the most critical factors influencing physical pellet quality. Restricting the addition of ingredients to low viscosity (fat, glycerol, etc..) and applying them in post-production with vacuum technology may increase physical quality of the feed pellets. These factors are sometimes neglected, and consequently the production parameters are managed poorly.

Importance of communication

With such unoptimised production physical feed pellet quality may be reduced. Negligence of these factors is mostly created through non-substantial communication between feed technologists and nutritionists. Therefore, both feed technologists and animal nutritionists need to learn to speak the same language which will bring the overall result in the form of a perfect pellet.

Perfect pellet happiness

It is of paramount importance that by using the scientific methods we identify how combined influencing factors may positively influence an optimal energy consumption during feed manufacturing. This could help feed manufacturers to choose different approaches that will improve physical and nutritional quality of the feed pellets and achieve a perfect cylindrical form of happiness.

Resourse: all about feed

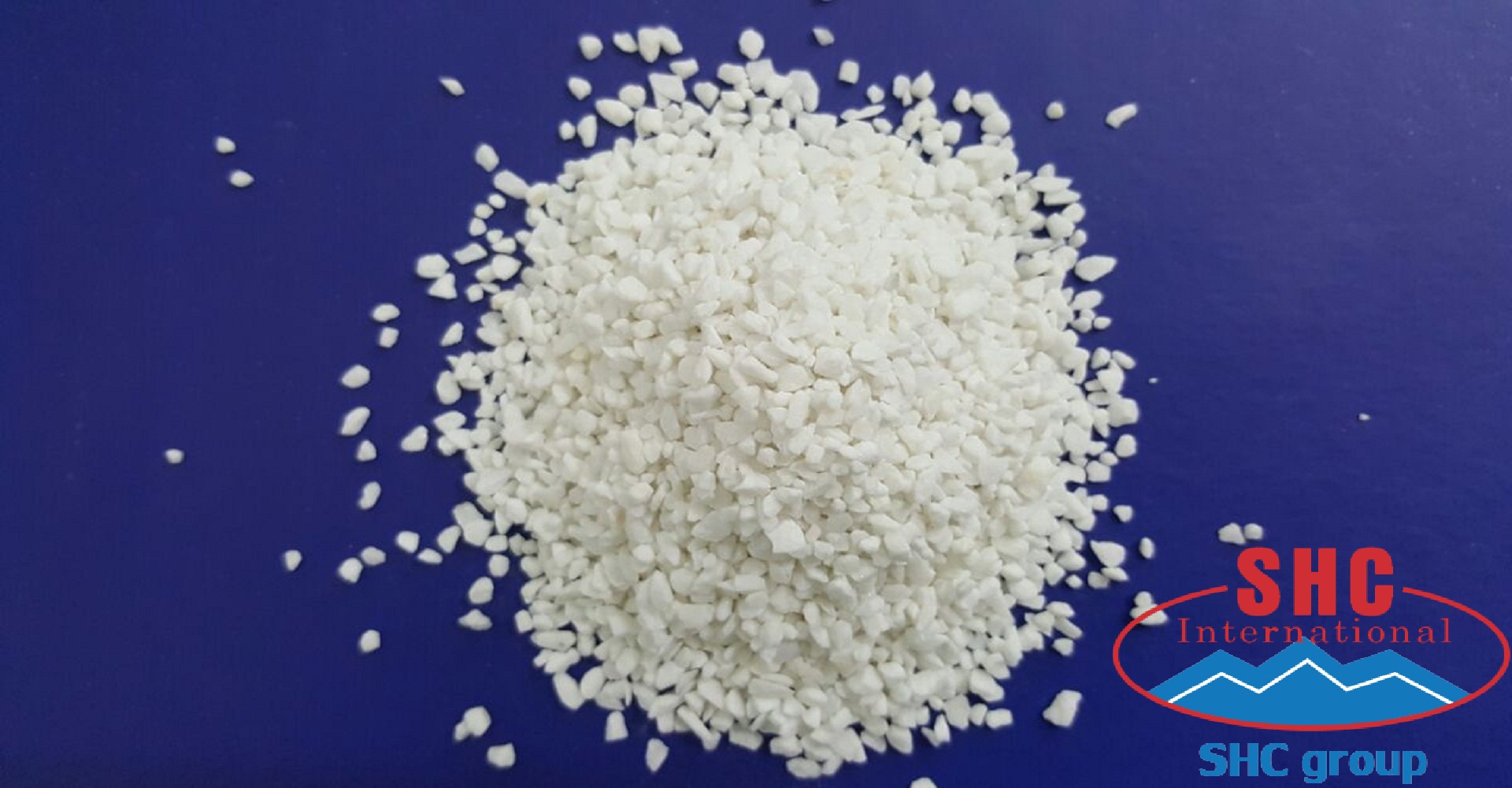

No.18 Son Ha Minerals is one of the leading manufacturer & top supplier of High Quality Limestone Powder and Granular Limestone for feed in Vietnam. Limestone is the most common source of calcium used in livestock feeding. Our limestone contains over 38% calcium and can safely be fed free choice (ad lib) mixed with salt.

Our factory is designed to produce 15000 MT / month of limestone granules and powder in various sizes. We can process sizes from 4-inch to 250 mesh (65 Microns). The plant is completely automatic and multiple control points to ensure consistent quality.

If you have interested in our products or need more information, please don't hesitate to contact with us.

No.18 Son Ha Minerals Co.,Ltd

Address: Mam Xoi Mountain, Thanh Son Commune, Kim Bang District, Ha Nam Province, VN

Telephone: +84 931 717 698

Fax: +84243.5190937

Hotline:+84 931 717 698 (Mr. Henry) // +84 932 222 698 (Ms. Anna)

Email: manager.shcgroup@gmail.com (Mr. Henry) // export1.shcgroup@gmail.com (Ms. Anna)

Skype: export1.shcgroup